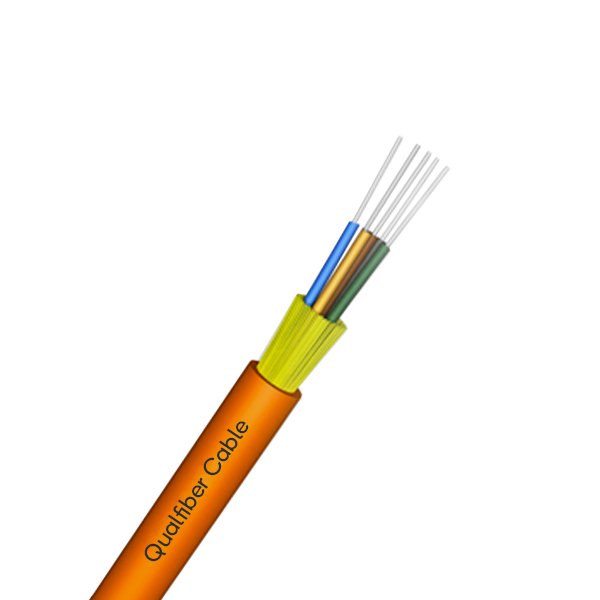

ADSS (non-metallic strengthening member, loose tube layer stranded filling type, polyethylene inner sheath, aramid yarn armor, polyethylene sheathed outdoor optical cable for communication). The structure of the optical cable is to sheath single-mode or multi-mode optical fiber into high-mode In the loose tube filled with waterproof compound made of high-density plastic, the center of the cable core is a non-metallic reinforcing member. For some fiber optic cables, the non-metallic center reinforcing member is extruded with a layer of polyethylene. The loose tube (and filling rope) is twisted around the central reinforcement to form a compact and round cable core. The gaps in the cable core are filled with water blocking compounds and a layer of polyethylene inner sheath is extruded. The aramid yarn is armored and extruded into a polyethylene outer sheath to form a cable.

Color:

Descrição

ADSS (non-metallic strengthening member, loose tube layer stranded filling type, polyethylene inner sheath, aramid yarn armor, polyethylene sheathed outdoor optical cable for communication). The structure of the optical cable is to sheath single-mode or multi-mode optical fiber into high-mode In the loose tube filled with waterproof compound made of high-density plastic, the center of the cable core is a non-metallic reinforcing member. For some fiber optic cables, the non-metallic center reinforcing member is extruded with a layer of polyethylene. The loose tube (and filling rope) is twisted around the central reinforcement to form a compact and round cable core. The gaps in the cable core are filled with water blocking compounds and a layer of polyethylene inner sheath is extruded. The aramid yarn is armored and extruded into a polyethylene outer sheath to form a cable.

Recursos:

●Precise optical fiber excess length control ensures that the optical cable has excellent tensile and temperature performance

●The loose tube material has good hydrolysis resistance, and the tube is filled with grease to protect the optical fiber

●The sheath material has good resistance to solar radiation

●All-dielectric fiber optic cable, especially suitable for self-supporting overhead aerial around electric field or lightning-prone areas

●Optical cable has outstanding tensile performance, and can be suitable for self-supporting overhead aerial up to 1500 meters

Inscrição

Self-supporting overhead, all dielectric lightning protection, directly hung on the power poles and towers for the communication route of the overhead high-voltage power transmission system

Construção de cabos

| Número de fibras | 12-288 cores | |||||||

| Corda de enchimento | 2-0 | |||||||

| Barreira de umidade | Sistema de bloqueio de água | |||||||

| Membro da força central | material | FRP / FRP com PE | ||||||

| Tamanho | 2.1mm | |||||||

| Enchimento de tubos | Composto de enchimento de tubos | |||||||

| enchimento | Tubo de PP / tubo de PVC | |||||||

| Bainha interna | material | EDUCAÇAO FISICA | ||||||

| Tubo solto | material | PBT | ||||||

| Diâmetro do | .22.2 (externo / interno) | |||||||

| Blindado exterior | material | Fita de alumínio / fita de aço ondulada | ||||||

| Bainha externa | material | PE / PEAD | ||||||

| Diâmetro do | 1.7 ± 0.2mm | |||||||

Cor da fibra

| Não. | 1 | 2 | 3 | 4 | 5 | 6 |

| Cor |  |

|

|

|

|

|

| Não. | 7 | 8 | 9 | 10 | 11 | 12 |

| Cor |  |

|

|

|

|

|

Cor do tubo

| Não. | 1 | 2 | 3 | 4 | 5 | 6 |

| Cor |  |

|

|

|

|

|

| Não. | 7 | 8 | 9 | 10 | 11 | 12 |

| Cor |  |

|

|

|

|

|

Característica mecânica do cabo

| testemunho | Diâmetro do cabo | peso | |||||

| 2 núcleos para 60core | 12 ± 0.5mm | 140 ± 5kg / km | |||||

| 72core | 13 ± 0,5 mm | 190 ± 5kg / km | |||||

| 96core | 14,5 ± 0,5 mm | 220 ± 5kg / km | |||||

| 144core | 16,5 ± 0,5 mm | 240 ± 10kg / km | |||||

| Rec.daily tensão máxima de trabalho | 88kn | ||||||

| Máx. Tensão de trabalho admissível | 32.7kn | ||||||

| Módulos de elasticidade | 37kn / mm2 | ||||||

| Raio de curvatura mínimo (mm) | Operação | 240mm | |||||

| instalação | 390mm | ||||||

| Carga extra | Carga extra 0,5% -0,7% | ||||||

| Gelo | 5mm | ||||||

| Velocidade do vento | 35m / s | ||||||

Característica da fibra

| Estilo de fibra | Unidade | SM G652 |

SM G652D |

MM 50/125 |

MM 62,5 / 125 |

MM OM3-300 |

|

| doença | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| atenuação | dB / km | ≤ | ≤ | ≤ | ≤3,0 / 1,0 | ≤3,0 / 1,0 | |

| 0,36 / 0,23 | 0,34 / 0,22 | 3.0 / 1.0 | ---- | ---- | |||

| Dispresion | 1550nm | Ps / (nm * km) | ---- | ≤18 | ---- | ---- | Dispresion |

| 1625nm | Ps / (nm * km) | ---- | ≤22 | ---- | ---- | ||

| Largura de banda | 850nm | MHZ.KM | ---- | ---- | ≧ 400 | 160 | Largura de banda |

| 1300nm | MHZ.KM | ---- | ---- | ≧ 800 | ≧ 500 | ||

| Comprimento de onda de dispersão zero | nm | 1300-1324 | ≧ 1302, ≤1322 |

---- | ---- | ≧ 1295, ≤1320 |

|

| Declive com desprendimento zero | nm | ≤0,092 | ≤0,091 | ---- | ---- | ---- | |

| PMD fibra individual máxima | ≤0,2 | ≤0,2 | ---- | ---- | ≤0,11 | ||

| Valor do link de design do PMD | Ps (nm2 * k m) |

≤0,12 | ≤0,08 | ---- | ---- | ---- | |

| Comprimento de onda de corte de fibra λc | nm | ≧ 1180, ≤1330 |

≧ 1180, ≤1330 |

---- | ---- | ---- | |

| Comprimento de λcc |

nm | ≤1260 | ≤1260 | ---- | ---- | ---- | |

| MFD | 1310nm | hum | 9,2 +/- 0,4 | 9,2 +/- 0,4 | ---- | ---- | ---- |

| 1550nm | hum | 10,4 +/- 0,8 | 10,4 +/- 0,8 | ---- | ---- | ---- | |

| Numérico (NA) |

---- | ---- | 0,200 + / -0,015 |

0,275 +/- 0. 015 |

0,200 +/- 0 0,015 |

||

| Etapa (média da ) |

dB | ≤0,05 | ≤0,05 | ≤0,10 | ≤0,10 | ≤0,10 | |

| Irregularidades no length and point |

dB | ≤0,05 | ≤0,05 | ≤0,10 | ≤0,10 | ≤0,10 | |

| Descontinuidade | |||||||

| Diferença de retroespalhamento coefficient |

dB / km | ≤0,05 | ≤0,03 | ≤0,08 | ≤0,10 | ≤0,08 | |

| Uniformidade de atenuação | dB / km | ≤0,01 | ≤0,01 | ||||

| Diâmetro do núcleo | hum | 50 +/- 1,0 | 62,5 +/- 2,5 | 50 +/- 1,0 | |||

| Diâmetro de revestimento | hum | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | |

| Não circularidade do revestimento | % | ≤1,0 | ≤1,0 | ≤1,0 | ≤1,0 | ≤1,0 | |

| Diâmetro de revestimento | hum | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | |

| Coating/chaffinch concentrically error |

hum | ≤12,0 | ≤12,0 | ≤12,0 | ≤12,0 | ≤12,0 | |

| Não circularidade do revestimento | % | ≤6,0 | ≤6,0 | ≤6,0 | ≤6,0 | ≤6,0 | |

| Erro de concentricidade do núcleo / revestimento | hum | ≤0,6 | ≤0,6 | ≤1,5 | ≤1,5 | ≤1,5 | |

| Curvatura (raio) | hum | ≤4 | ≤4 | ---- | ---- | ---- | |

Pacote

| 1. material de embalagem: tambor de madeira | |||||||

| 2.Comprimento da embalagem: O comprimento padrão do cabo deve ser de 2 km. Outro comprimento do cabo também está disponível | |||||||

| se exigido pelo cliente |

Marcação de cabos e bobinas

A bainha do cabo deve ser marcada com caracteres brancos, de acordo com a exigência do cliente.

Write your message here and send it to us