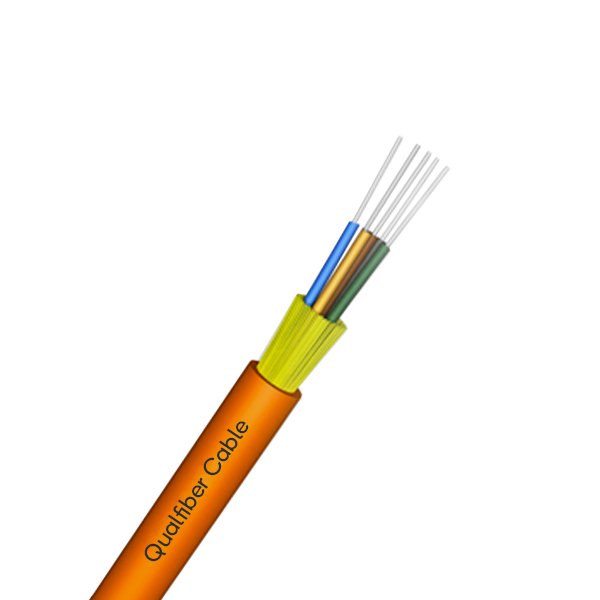

ADSS (non-metallic strengthening member, loose tube layer stranded filling type, polyethylene inner sheath, aramid yarn armor, polyethylene sheathed outdoor optical cable for communication). The structure of the optical cable is to sheath single-mode or multi-mode optical fiber into high-mode In the loose tube filled with waterproof compound made of high-density plastic, the center of the cable core is a non-metallic reinforcing member. For some fiber optic cables, the non-metallic center reinforcing member is extruded with a layer of polyethylene. The loose tube (and filling rope) is twisted around the central reinforcement to form a compact and round cable core. The gaps in the cable core are filled with water blocking compounds and a layer of polyethylene inner sheath is extruded. The aramid yarn is armored and extruded into a polyethylene outer sheath to form a cable.

Color:

기술

ADSS (non-metallic strengthening member, loose tube layer stranded filling type, polyethylene inner sheath, aramid yarn armor, polyethylene sheathed outdoor optical cable for communication). The structure of the optical cable is to sheath single-mode or multi-mode optical fiber into high-mode In the loose tube filled with waterproof compound made of high-density plastic, the center of the cable core is a non-metallic reinforcing member. For some fiber optic cables, the non-metallic center reinforcing member is extruded with a layer of polyethylene. The loose tube (and filling rope) is twisted around the central reinforcement to form a compact and round cable core. The gaps in the cable core are filled with water blocking compounds and a layer of polyethylene inner sheath is extruded. The aramid yarn is armored and extruded into a polyethylene outer sheath to form a cable.

풍모:

●Precise optical fiber excess length control ensures that the optical cable has excellent tensile and temperature performance

●The loose tube material has good hydrolysis resistance, and the tube is filled with grease to protect the optical fiber

●The sheath material has good resistance to solar radiation

●All-dielectric fiber optic cable, especially suitable for self-supporting overhead aerial around electric field or lightning-prone areas

●Optical cable has outstanding tensile performance, and can be suitable for self-supporting overhead aerial up to 1500 meters

신청

Self-supporting overhead, all dielectric lightning protection, directly hung on the power poles and towers for the communication route of the overhead high-voltage power transmission system

케이블 공사

| 섬유 수 | 12-288 cores | |||||||

| 채우는 밧줄 | 2-0 | |||||||

| 수분 장벽 | 물 차단 시스템 | |||||||

| 중앙 강도 멤버 | 재료 | PE를 가진 FRP / FRP | ||||||

| 크기 | 2.1mm | |||||||

| 튜브 충전 | 튜브 충전 컴파운드 | |||||||

| 필러 | PP 튜브 / PVC 튜브 | |||||||

| 내부 칼집 | 재료 | 체육 | ||||||

| 느슨한 튜브 | 재료 | PBT | ||||||

| 직경 | Ф2.2 (외부 / 내부) | |||||||

| 외부 장갑 | 재료 | 알루미늄 테이프 / 골판지 테이프 | ||||||

| 외피 | 재료 | PE / HDPE | ||||||

| 직경 | 1.7 ± 0.2mm | |||||||

섬유 색상

| 아니. | 1 | 2 | 3 | 4 | 5 | 6 |

| 색깔 |  |

|

|

|

|

|

| 아니. | 7 | 8 | 9 | 10 | 11 | 12 |

| 색깔 |  |

|

|

|

|

|

튜브 색상

| 아니. | 1 | 2 | 3 | 4 | 5 | 6 |

| 색깔 |  |

|

|

|

|

|

| 아니. | 7 | 8 | 9 | 10 | 11 | 12 |

| 색깔 |  |

|

|

|

|

|

케이블 기계적 특성

| 핵심 | 케이블 직경 | 무게 | |||||

| 2 코어 ~ 60 코어 | 12 ± 0.5mm | 140 ± 5kg / km | |||||

| 72 코어 | 13 ± 0.5mm | 190 ± 5kg / km | |||||

| 96 코어 | 14.5 ± 0.5mm | 220 ± 5kg / km | |||||

| 144 코어 | 16.5 ± 0.5mm | 240 ± 10kg / km | |||||

| 권장 일일 최대 작업 장력 | 88kn | ||||||

| 최대 허용되는 장력 | 32.7kn | ||||||

| 탄성 계수 | 37kn / mm2 | ||||||

| 최소 굽힘 반경 (mm) | 조작 | 240mm | |||||

| 설치 | 390mm | ||||||

| 추가 하중 | 추가 하중 0.5 % -0.7 % | ||||||

| 빙 | 5mm | ||||||

| 바람 속도 | 35m / s | ||||||

섬유 특성

| 섬유 스타일 | 단위 | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5 / 125 |

MM OM3-300 |

|

| 질환 | 내지 | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| 감쇠 | dB / km | ≤ | ≤ | ≤ | ≤3.0 / 1.0 | ≤3.0 / 1.0 | |

| 0.36 / 0.23 | 0.34 / 0.22 | 3.0 / 1.0 | ---- | ---- | |||

| 해석 | 1550nm | Ps / (nm * km) | ---- | ≤18 | ---- | ---- | 해석 |

| 1625nm | Ps / (nm * km) | ---- | ≤22 | ---- | ---- | ||

| 밴드 | 850nm | MHZ.KM | ---- | ---- | ≥400 | ≥160 | 밴드 |

| 1300nm | MHZ.KM | ---- | ---- | ≧ 800 | ≥500 | ||

| 제로 분산 파장 | 내지 | 1300-1324 | ≥1302, ≤1322 |

---- | ---- | ≥ 1295, ≤1320 |

|

| 무재해 경사 | 내지 | ≤0.092 | ≤0.091 | ---- | ---- | ---- | |

| PMD 최대 개별 섬유 | ≤0.2 | ≤0.2 | ---- | ---- | ≤0.11 | ||

| PMD 디자인 링크 가치 | Ps (nm2 * k m) |

≤0.12 | ≤0.08 | ---- | ---- | ---- | |

| 섬유 차단 파장 λc | 내지 | ≥ 1180, ≤1330 |

≥1180, ≤1330 |

---- | ---- | ---- | |

| 케이블 sutoff 파장 λcc |

내지 | ≤1260 | ≤1260 | ---- | ---- | ---- | |

| MFD | 1310nm | 음 | 9.2 +/- 0.4 | 9.2 +/- 0.4 | ---- | ---- | ---- |

| 1550nm | 음 | 10.4 +/- 0.8 | 10.4 +/- 0.8 | ---- | ---- | ---- | |

| 수치 조리개 (NA) |

---- | ---- | 0.200 + / -0.015 |

0.275 +/- 0. 015 |

0.200 +/- 0.015 |

||

| 단계 (양방향 ) |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| 섬유 length and point |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| 불연속 | |||||||

| 차이 후방 산란 계수 |

dB / km | ≤0.05 | ≤0.03 | ≤0.08 | ≤0.10 | ≤0.08 | |

| 감쇠 균일 성 | dB / km | ≤0.01 | ≤0.01 | ||||

| 코어 직경 | 음 | 50 +/- 1.0 | 62.5 +/- 2.5 | 50 +/- 1.0 | |||

| 클래딩 직경 | 음 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | |

| 비순환 클래딩 | % | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

| 코팅 직경 | 음 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | |

| Coating/chaffinch 오류 |

음 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | |

| 비 원형 코팅 | % | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | |

| 코어 / 클래딩 동심도 오류 | 음 | ≤0.6 | ≤0.6 | ≤1.5 | ≤1.5 | ≤1.5 | |

| 컬 (반지름) | 음 | ≤4 | ≤4 | ---- | ---- | ---- | |

꾸러미

| 1. 포장 재료 : 나무 드럼 | |||||||

| 2. 포장 길이 : 케이블의 표준 길이는 2km입니다. 다른 케이블 길이도 사용 가능 | |||||||

| 고객이 요구하는 경우 |

케이블 마킹 및 케이블 릴 마킹

케이블 외피는 고객의 요구 사항에 따라 흰색 문자로 표시해야합니다.

Write your message here and send it to us