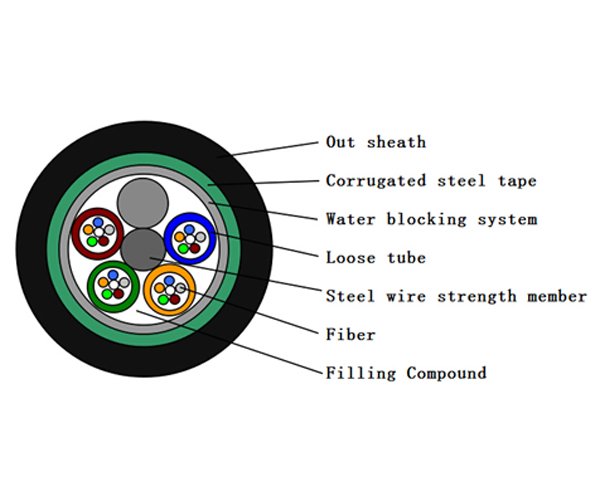

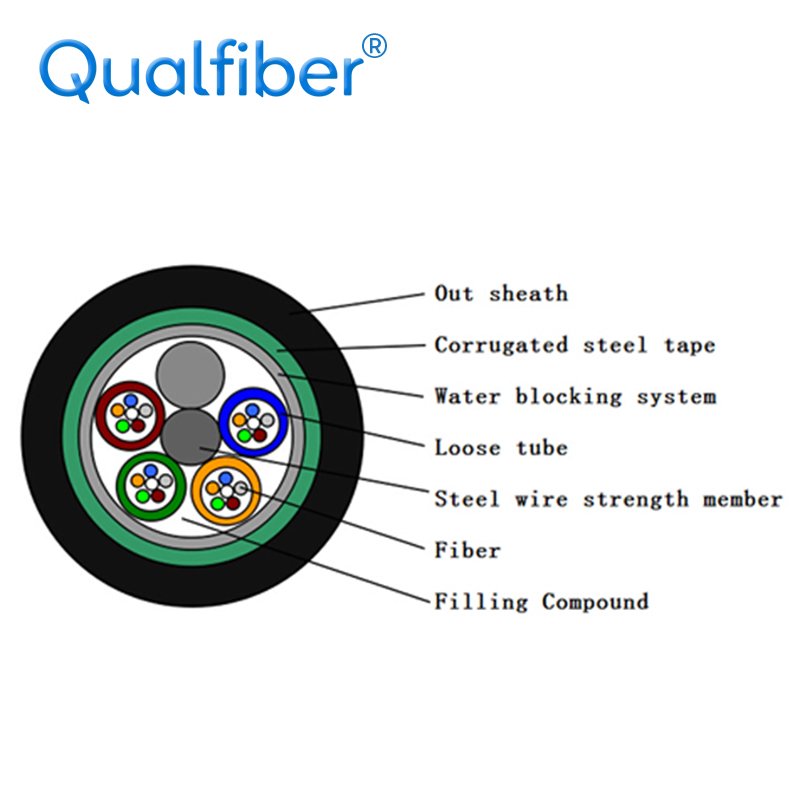

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Color:

Beschreibung

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Kabelkonstruktion

| Anzahl der Fasern | 2~144 F | |||||||

| Feuchtigkeitsbarriere | Wasserblockiersystem | |||||||

| Zentrales Kraftelement | Material | Stahldraht / FRP / FRP mit PE-Abdeckung | ||||||

| Größe | 1,5 mm ~ 2,0 mm | |||||||

| Lose Röhre | Material | PBT | ||||||

| Modenfelddurchmesser | Ф2.2 (außen / innen) | |||||||

| Rohrfüllung | Rohrfüllmasse | |||||||

| Panzerung | Material | Wellstahlband | ||||||

| Außenhülle | Material | PE, HDPE | ||||||

| Modenfelddurchmesser | 1,70 ± 0,2 mm | |||||||

Faserfarbe

| Nein. | 1 | 2 | 3 | 4 | 5 | 6 |

| Farbe |  |

|

|

|

|

|

| Nein. | 7 | 8 | 9 | 10 | 11 | 12 |

| Farbe |  |

|

|

|

|

|

Röhrenfarbe

| Nein. | 1 | 2 | 3 | 4 | 5 | 6 |

| Farbe |  |

|

|

|

|

|

| Nein. | 7 | 8 | 9 | 10 | 11 | 12 |

| Farbe |  |

|

|

|

|

|

Kabel Mechanische Eigenschaften

| Ader | Kabeldurchmesser | Gewicht | |||||

| 2 Kerne bis 60 Kerne | 10,0 ± 0,3 mm | 115 ± 5 kg / km | |||||

| 72 Kerne | 10,5 ± 0,3 mm | 120 ± 5 kg / km | |||||

| 96 Kerne | 12,5 ± 0,3 mm | 180 ± 5 kg / km | |||||

| 144 Kerne | 14,5 ± 0,3 mm | 245 ± 5 kg / km | |||||

| Min. Biegeradius (mm) | Langfristig | 10D | |||||

| Min. Biegeradius Radius(mm) |

Kurzfristig | 20D | |||||

| Min. Zulässige Tensile Strength(N) |

Langfristig | 600 | |||||

| Min. Zulässige Tensile Strength(N) |

Kurzfristig | 1500 | |||||

| Quetschlast (N / 100mm) | Langfristig | 300 | |||||

| Quetschlast (N / 100mm) | kurzfristig | 1000 | |||||

| Betrieb temperature (℃) |

-40 + 70 | ||||||

| Einbautemperatur temperature(℃) |

-20 + 60 | ||||||

Fasereigenschaft

| Faserstil | Einheit | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5/125 |

MM OM3-300 |

|

| Bedingung | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| Dämpfung | dB / km | ≤ | ≤ | ≤ | ≤ 3,0 / 1,0 | ≤ 3,0 / 1,0 | |

| 0,36 / 0,23 | 0,34 / 0,22 | 3,0 / 1,0 | - | - | |||

| Dispersion | 1550 nm | Ps / (nm * km) | - | ≤18 | - | - | Dispersion |

| nm | Ps / (nm * km) | - | ≤22 | - | - | ||

| Bandbreite | 850 nm | MHZ.KM | - | - | ≧ 400 | ≧ 160 | Bandbreite |

| nm | MHZ.KM | - | - | ≧ 800 | ≧ 500 | ||

| Wellenlänge ohne Dispersion | nm | 1300-1324 | 2 1302, ≤1322 |

- | - | ≤ 1295, ≤1320 |

|

| Null-Dispersions-Steigung | nm | ≤ 0,092 | ≤ 0,091 | - | - | - | |

| PMD Maximum Individual Fiber | ≤0,2 | ≤0,2 | - | - | ≤ 0,11 | ||

| PMD Design Link Value | Ps (nm2 · m) |

≤ 0,12 | ≤ 0,08 | - | - | - | |

| Fasergrenzwellenlänge λc | nm | ≤ 1180, ≤1330 |

≤ 1180, ≤1330 |

- | - | - | |

| Kabelgrenzwellenlänge wavelength λcc |

nm | ≤1260 | ≤1260 | - | - | - | |

| MFD | 1310 nm | Äh | 9,2 +/- 0,4 | 9,2 +/- 0,4 | - | - | - |

| 1550 nm | Äh | 10,4 +/- 0,8 | 10,4 +/- 0,8 | - | - | - | |

| Numerische Aperture(NA) |

- | - | 0,200 + / -0.015 |

0,275 +/- 0. 015 |

0,200 +/- .015 |

||

| Schritt (Mittelwert der bidirektionalen measurement) |

dB | ≤ 0,05 | ≤ 0,05 | ≤ 0,10 | ≤ 0,10 | ≤ 0,10 | |

| Unregelmäßigkeiten über Faserlänge length and point |

dB | ≤ 0,05 | ≤ 0,05 | ≤ 0,10 | ≤ 0,10 | ≤ 0,10 | |

| Diskontinuität | |||||||

| Differenz Backscatter - coefficient |

dB / km | ≤ 0,05 | ≤0,03 | ≤ 0,08 | ≤ 0,10 | ≤ 0,08 | |

| Gleichmäßigkeit der Dämpfung | dB / km | ≤ 0,01 | ≤ 0,01 | ||||

| Kerndurchmesser | Äh | 50 +/- 1,0 | 62,5 +/- 2,5 | 50 +/- 1,0 | |||

| Verkleidungsdurchmesser | Äh | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | |

| Unrundheit der Verkleidung | %. | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | |

| Beschichtungsdurchmesser | Äh | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | |

| Beschichtung / Buchfink concentrically error |

Äh | ≤ 12,0 | ≤ 12,0 | ≤ 12,0 | ≤ 12,0 | ≤ 12,0 | |

| Beschichtung nicht kreisförmig | %. | ≤6,0 | ≤6,0 | ≤6,0 | ≤6,0 | ≤6,0 | |

| Kern / Mantel-Konzentrizitätsfehler | Äh | ≤ 0,6 | ≤ 0,6 | 1,5 | 1,5 | 1,5 | |

| Curl (Radius) | Äh | ≤4 | ≤4 | - | - | - | |

Paket

| 1. Verpackungsmaterial: Holztrommel | |||||||

| 2.Packlänge: Die Standardlänge des Kabels beträgt 2 km. Eine weitere Kabellänge ist ebenfalls erhältlich | |||||||

| auf Wunsch des Kunden |

Kabelmarkierung und Kabelspulenmarkierung

Der Kabelmantel ist gemäß den Anforderungen des Kunden mit weißen Zeichen zu kennzeichnen.

Write your message here and send it to us