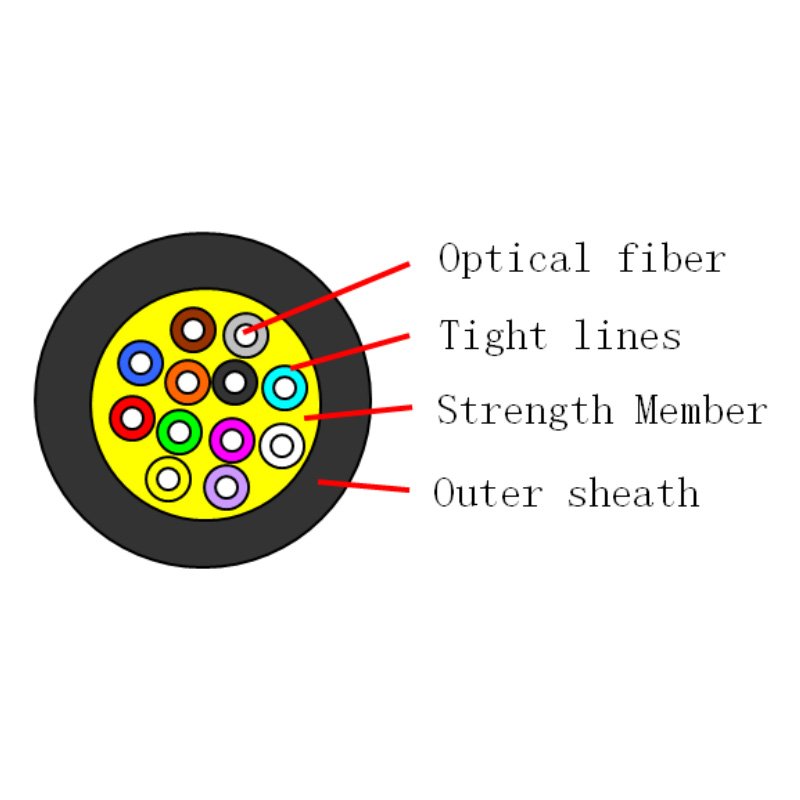

GJFJH(GJYFJH/GJYFJCH) non-metallic strength member, LSZH sheath, non-self-supporting round optical drop cable (or self-supporting round optical drop cable), the optical cable is directly covered with high bonding strength outside the single-mode or multi-mode fiber The tight sleeve material is made of tight sleeve fiber, which uses high-strength aramid as the strengthening element, and is made by extruding a layer of LSZH on the outside. The structure of the self-supporting circular optical drop cable is to increase the metal steel strand suspension wire.

Color:

Beschreibung

GJFJH(GJYFJH/GJYFJCH) non-metallic strength member, LSZH sheath, non-self-supporting round optical drop cable (or self-supporting round optical drop cable), the optical cable is directly covered with high bonding strength outside the single-mode or multi-mode fiber The tight sleeve material is made of tight sleeve fiber, which uses high-strength aramid as the strengthening element, and is made by extruding a layer of LSZH on the outside. The structure of the self-supporting circular optical drop cable is to increase the metal steel strand suspension wire.

Technische Daten

| Anzahl der Kabel | 12 | |||

| Fasermodell | OM3 | |||

| Enge Linien | Material | LSZH | ||

| Dicke ± 0,03 mm | 0,32 | |||

| Durchmesser ± 0,06 mm | 0,9 | |||

| Stärkemitglied | Material | Aramidgarn | ||

| Außenhülle | Material | LSZH | ||

| Dicke ± 0,2 mm | 1.0 | |||

| Farbe | violett | |||

| Kabeldurchmesser ± 0,2 mm | 6.2 | |||

| Cable Wetght(±5)kg/km | 40 | |||

| Dämpfung | 1310 nm | dB / km | 0,4 | |

| 1550 nm | 0,3 | |||

| Zulässige Zugfestigkeit | Kurzfristig | N. | 660 | |

| Langfristig | 200 | |||

| Zulässige Quetschfestigkeit | Kurzfristig | N / 100mm | 1000 | |

| Langfristig | 200 | |||

| Mindest. Biegungsradius | Ohne Spannung | 10,0 × Kabel-φ | ||

| Unter maximaler Spannung | 20,0 × Kabel-φ | |||

| Temperaturbereich (℃) |

Einbautemperatur | -20 ~ + 60 | ||

| Transport & Lagerung | -40 ~ + 70 | |||

| Betrieb | -40 ~ + 70 | |||

Enge Linien Farben

| NEIN. | 1 | 2 | 3 | 4 | 5 | 6 |

| Farbe | Blau | Orange | Grün | braun | grau | Weiß |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| rot | schwarz | Gelb | Violett | Rosa | Aqua | |

Haupttest der mechanischen und Umweltleistung

| Charakteristisch | Charakteristisch | Charakteristisch | Charakteristisch |

| Optische Eigenschaften | |||

| Dämpfung | 1310 nm 1550nm 1625nm |

≤ ≤0,21 0,23 |

dB / km dB / km dB / km |

| Dämpfungswert | 1310 ~ 16250 nm | ≤ 0,0 35 | dB / km |

| Differenzdämpfung zwischen | 1285 ≤ 1310nm 1525~1575nm 1550nm 1480~1580nm 1550nm |

≤ 0,03 ≤ 0,02 ≤ 0,04 |

dB / km dB / km dB / km |

| Makro - Biege Sensibilität | @ 1550nm @1625nm @1550nm @1625nm |

≤ 0,25 ≤ 1.0 ≤ 0,75 ≤ 1,5 |

Radius 15 mm, 10 Kreis Radius 15mm, 10 circle Radius 10mm, 1 circle Radius 10mm, 1circle |

| Wellenlänge ohne Dispersion | 1300~ ~1324 | nm | |

| Eine Neigung ohne Dispersion | ≤ 0,092 | ps / (nm 2 km) | |

| Dispersionskoeffizient | @ 1285-1340 @1550nm @1625nm |

-3,4-3,4 ≤18.0 ≤22.0 |

ps / (nm 2 km) |

| Wellenlänge der Kabelabschaltung( λcc) | ≤ 1260 | nm | |

| Mode field Modenfelddurchmesser (MFD) | 1310 nm 1550nm |

8,4 -9,2 9.3-10.3 |

μm μm |

| Attenuation Diskontinuitäten | 1310 nm 1550nm |

≤ 0,05 ≤ 0,05 |

dB dB |

| Geometrische Eigenschaften | |||

| Kerndurchmesser | 0,7 | μm | |

| Verkleidungsdurchmesser | 125± 0,7 | ||

| Verkleidungsrundheit | ≤ 0,7 | %. | |

| Beschichtungsdurchmesser | 245± 7 | μm | |

| Die Beschichtung / packag eine e Rundlauffehler | ≤ 12,0 | ||

Write your message here and send it to us