Part number definition

GY——Communication room (field) outdoor optical cable

X ——Cable center tube (cover) structure

T ——filled structure

W ——Steel polyethylene bonded sheath with steel wire (referred to as W sheath)

| GY | Communication room (field) outdoor optical cable | none | no reinforcement | B | Flat shape | A | Aluminum-polyethylene bonded sheath | 5 | Corrugated steel belt | Codename | Coating or jacket code | A1a | IEC and GB/T | G.651 | ||||||

| GH | Submarine Optical Cable for Communication | F | Non-metallic reinforcement | C | Self-supporting structure | G | Steel sheath | 44 | Double thick round steel wire | 1 | Fiber cover | A1b | IEC and GB/T | G.651 | ||||||

| GJ | Optical cable in communication room (office) | G | Metal heavy reinforcement | D | Fiber ribbon structure | L | Aluminum sheath | 4 | Single thick round steel wire | 2 | Polyethylene protection tube | A1c | IEC and GB/T | G.651 | ||||||

| GR | Flexible Optical Cable for Communication | H | Non-metallic heavy-duty reinforcement | E | Oval shape | Q | Lead sheath | 33 | Double thin round steel wire | 3 | Polyethylene sleeve | A1d | IEC and GB/T | G.651 | ||||||

| GS | Optical fiber cable in communication equipment | G | Skeleton trough structure | S | Steel-polyethylene bonded magnetic protection | 3 | Single thin round steel wire | 4 | Polyethylene sleeve and nylon sleeve | B1.1 (B1) | Non-dispersion shifted fiber | G652 | ||||||||

| GT | Special optical cable for communication | J | Fiber tight sleeve coating structure | U | Polyurethane sheath | 2 | Double steel belt | 5 | PVC sleeve | B1.2 | Cut-off wavelength shifted fiber | G654 | ||||||||

| GW | Metal-free optical cable for communication | R | Inflatable structure | V | PVC sheath | 0 | No armor layer | B1.3 | IEC and GB/T | G.652C | ||||||||||

| GM | Mobile optical cable for communication | T | Grease filled structure | W | Steel-polyethylene bonded sheath with parallel steel wires | B2 | Dispersion shift type optical cable | G653 | ||||||||||||

| X | Cable bundle tube (coating) structure | Y | Polyethylene sheath | B4 | Non-zero dispersion shifted fiber | G655 | ||||||||||||||

| Z | Flame retardant |

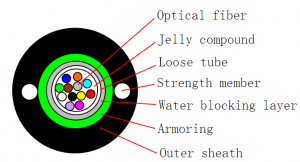

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. The tube is wrapped with a layer of PSP longitudinally. Between the PSP and the loose tube water-blocking material is applied to keep the cable compact and watertight. Two parallel steel wires are placed at the two sides of the steel tape. The cable is completed with a polyethylene (PE) sheath.

Product description

● The center loose tube protects the coated fiber once

● The optical fiber is concentrated in the center of the cable, and the strength members are distributed on both sides of the cable sheath

Features

● Small outer diameter, light weight, convenient construction

● Stable fiber excess length control

● After the cable is formed, the additional attenuation of the fiber is close to zero, and the dispersion value does not change

● Excellent environmental performance

Applicable laying

● Aerial laying

● Wear tube/blowing in tube

● Buried/underground

Structure

● The central loose tube protects the primary coated optical fiber

● The optical fiber is concentrated in the center of the cable, and the reinforcements are distributed on both sides of the cable sheath

● Water blocking layer is provided between the steel belt and the cable core

● Double-sided plastic-coated corrugated steel belt -Polyethylene bonded outer sheath

● Double steel wire parallel reinforcement

Performance characteristics

● Excellent water blocking layer, with good anti-seepage ability

● The outer sheath of steel tape is bonded and metal reinforced, with excellent tension performance

● The central design of the beam tube minimizes the influence of the optical fiber on the anti-lateral force of the optical cable

Note: It can be designed in rows of non-metallic structures according to user requirements

Scope of application

● Long-distance communication, inter-office communication, more suitable for southern regions

Technical parameter

| Fiber optic cable core number | Optical cable outer diameter(MM) | Cable weight(Kg/KM) | Minimum bending radius | Allowable tension (N) | Allowable side pressure (N/100MM) | |

| Static | dynamic | short term | long term | short term | long term | |

| 2-12 | 8.9 | 90 | 10 times the cable diameter | 20 times the cable diameter | 1500 | 600 | 1000 | 300 |

| 14-24 | 10.2 | 110 | 1500 | 600 | 1000 | 300 |

Post time: Feb-09-2021