Part number definition

| GY | Communication room (field) outdoor optical cable | none | no reinforcement | B | Flat shape | A | Aluminum-polyethylene bonded sheath | 5 | Corrugated steel belt | Codename | Coating or jacket code | A1a | IEC and GB/T | G.651 | ||||||

| GH | Submarine Optical Cable for Communication | F | Non-metallic reinforcement | C | Self-supporting structure | G | Steel sheath | 44 | Double thick round steel wire | 1 | Fiber cover | A1b | IEC and GB/T | G.651 | ||||||

| GJ | Optical cable in communication room (office) | G | Metal heavy reinforcement | D | Fiber ribbon structure | L | Aluminum sheath | 4 | Single thick round steel wire | 2 | Polyethylene protection tube | A1c | IEC and GB/T | G.651 | ||||||

| GR | Flexible Optical Cable for Communication | H | Non-metallic heavy-duty reinforcement | E | Oval shape | Q | Lead sheath | 33 | Double thin round steel wire | 3 | Polyethylene sleeve | A1d | IEC and GB/T | G.651 | ||||||

| GS | Optical fiber cable in communication equipment | G | Skeleton trough structure | S | Steel-polyethylene bonded magnetic protection | 3 | Single thin round steel wire | 4 | Polyethylene sleeve and nylon sleeve | B1.1 (B1) | Non-dispersion shifted fiber | G652 | ||||||||

| GT | Special optical cable for communication | J | Fiber tight sleeve coating structure | U | Polyurethane sheath | 2 | Double steel belt | 5 | PVC sleeve | B1.2 | Cut-off wavelength shifted fiber | G654 | ||||||||

| GW | Metal-free optical cable for communication | R | Inflatable structure | V | PVC sheath | 0 | No armor layer | B1.3 | IEC and GB/T | G.652C | ||||||||||

| GM | Mobile optical cable for communication | T | Grease filled structure | W | Steel-polyethylene bonded sheath with parallel steel wires | B2 | Dispersion shift type optical cable | G653 | ||||||||||||

| X | Cable bundle tube (coating) structure | Y | Polyethylene sheath | B4 | Non-zero dispersion shifted fiber | G655 | ||||||||||||||

| Z | Flame retardant |

Product description

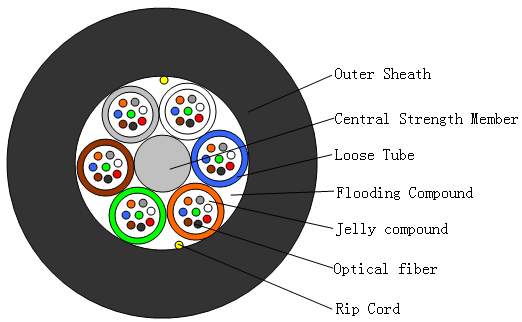

GYFTY (non-metallic strengthening member, loose tube stranded and filled, polyethylene sheathed outdoor optical fiber cable for communication) The structure of the optical cable is to sheath a single-mode or multi-mode optical fiber into a high-modulus plastic filled with waterproof compound loose In the casing. The center of the cable core is a non-metallic reinforced core (FRP). For certain fiber optic cables, a layer of polyethylene (PE) is extruded outside the non-metallic reinforced core or a non-metallic reinforced yarn is added to the cable core. line. The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core. The gaps in the cable core are filled with water blocking compounds and polyethylene sheaths.

Features

●Precise control of the excess length of the optical fiber ensures that the optical cable has good tensile performance and temperature characteristics

●PBT loose tube material has good hydrolysis resistance, and the tube is filled with special grease to protect the optical fiber

●Optical cable has excellent flexibility and bending resistance

●Optical cables are all non-metallic structures, light in weight, easy to lay, and excellent in electromagnetic resistance

●Smooth outer sheath enables the optical cable to have a smaller coefficient of friction during installation

●PE sheath has good resistance to solar radiation

●The following measures are adopted to ensure the waterproof performance of the optical cable: the loose tube is filled with special waterproof compound; the cable core is completely filled

Applicable laying

Power system, heavy lightning and places with severe electromagnetic interference

Structure

|

|

Technical Data

|

Number of cable cores |

/ |

2~30 |

32~60 |

62~72 |

74~96 |

98~120 |

122~144 |

||

|

Structure |

/ |

1+5 |

1+5 |

1+6 |

1+8 |

1+10 |

1+12 |

||

|

Type of fiber |

/ |

G.652D |

|||||||

|

Centre Reinforcement |

Materials |

mm |

FRP |

||||||

| Dimensions (average) |

1.5 |

1.5 |

2.1 |

2.1 |

2.1 |

2.1 |

|||

|

Cushion |

Materials |

mm |

Medium density polyethylene |

||||||

| Dimensions (average) |

— |

— |

— |

3.4 |

4.7 |

6.2 |

|||

|

Loose casing |

Materials |

mm |

PBT |

||||||

| Diameter (average) |

1.8 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

|||

| Wall thickness (average) |

0.32 |

0.35 |

0.35 |

0.35 |

0.35 |

0.35 |

|||

|

Maximum number of cores per tube |

6 |

12 |

12 |

12 |

12 |

12 |

|||

|

Plastic tube chromatography |

Total chromatography |

||||||||

|

Length of fiber optic |

% |

0.7~0.8 |

|||||||

|

Water barrier |

Materials |

/ |

Cable paste |

||||||

|

Outer sheath |

Materials |

mm |

Medium density polyethylene |

||||||

|

Thickness (average) |

Nominal value :1.8 Minimum :1.5 Average :1.6 |

||||||||

|

Optical cable diameter (average) |

mm |

8.5 |

9.1 |

9.7 |

11.0 |

12.3 |

13.8 |

||

|

Optical cable weight (approximate) |

kg/km |

55 |

70 |

83 |

110 |

135 |

170 |

||

|

Maximum attenuation coefficient |

nm 1310 |

dB /km |

0.35 |

||||||

|

1550 nm |

0.21 |

||||||||

|

tensile force |

Long term |

N |

600 |

||||||

|

Short term |

1500 |

||||||||

|

Flattening |

Long term |

N/100mm |

300 |

||||||

|

Short term |

1000 |

||||||||

|

Bending radius |

Static |

mm |

10x cable diameter |

||||||

|

Dynamic |

20x cable diameter |

||||||||

|

Temperature |

Installation |

℃ |

-20~+60 |

||||||

|

Storage and transportation |

-40~+70 |

||||||||

|

Work |

-40~+70 |

||||||||

|

Identification |

QUALFIBER GYFTY-××B1YD/T 901-2009××××M year (or according to customer requirements) |

||||||||

Post time: Feb-16-2021